Our CFF™ family of products offers easy-to-use nonwovens with a variety of uses in liquid filtration. From pharmaceutical and medical filtration, to agricultural applications, to household uses such as pool and spa filters, it’s easier to create a reliable and uniform product with these quality ANCI nonwovens. Get the edge over standard single-layer spunbond materials, discover how CFF™ fits into your application.

What Makes CFF™ Unique?

The way we produce CFF™ is what sets it apart from the industry standard spunbond. The composition of our material creates a unique fiber to fiber bond that increases consistency for more efficient liquid filtration. Not only that, CFF™ is easier to work with – enabling you to perfect production and create a higher quality filtration product. Based on your desired end product and the required specifications, CFF™ can be produced in both flat bond and point bond grades.

Our process results in a material that’s more uniform and easier to work with than a typical spunbond nonwoven, meaning it can be quickly and consistently processed into your final product.

Easier to Process, Better to Use

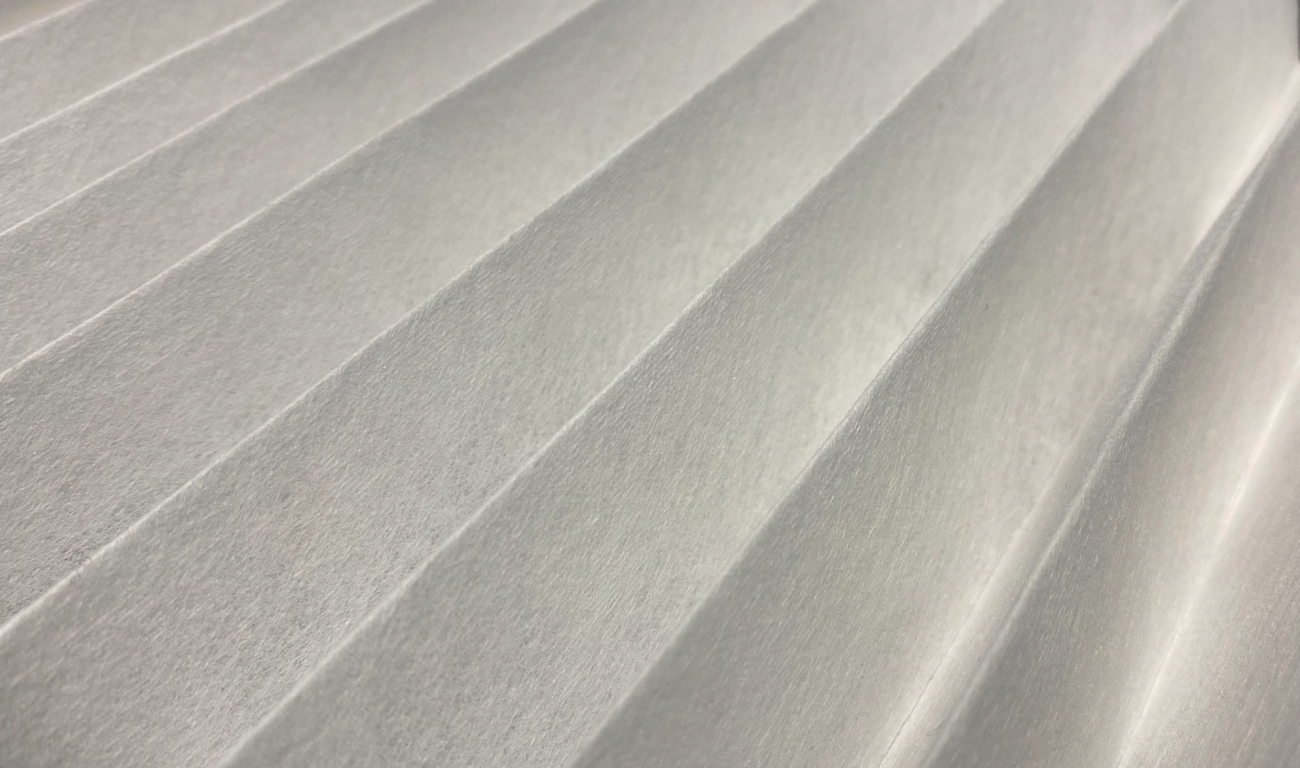

A number of benefits make CFF™ easier to work with. The stiffness of CFF™ means it’s easy to use in cutting, sewing, and pleating processes, and it is readily slit to the specific width that any application calls for. With excellent tensile and tear strength, it stands up to regular use and resists unwanted tearing – while the unique bonding process ensures that CFF™ layers don’t delaminate. Plus, with better fiber tie-down than a comparable spunbond, CFF™ is less prone to raised fibers caused by abrasion.

Multiple Specifications

CFF™ comes in two varieties; a standard flat bonded version and a high flow point bonded variety. Among those two varieties are grades of different basis weight and thicknesses – please reach out to us for more information on available specifications. Below are the two major varieties:

CFF™

Standard CFF™ features exceptional uniformity, creating a 15%-20% increase in filtration efficiency of midsize (20-40 micrometers) particles when compared to spunbond of a similar weight.

High Flow CFF™

Point bonded for higher air permeability, High Flow CFF™ produces a lower pressure drop for applications where high flow is a necessity.

Exceptional Performance

Liquid filtration includes a wide array of use cases, and CFF™ nonwovens have been proven in a variety of applications.

- CFF™ materials are food contact compliant per FDA 21CFR-177-1630

- They perform better than the typical spunbond as membrane support in medical and pharmaceutical applications due to improved spot to spot uniformity.

- CFF™ materials display higher durability in applications such as coolant filtration.

- They have better filtration efficiency than the leading industry standard spunbond cartridges in pool and spa applications.

Discover a Better Nonwoven for Your Filtration Product

With easy processability, high durability, and proven effectiveness against typical spunbonds, the CFF™ family of nonwoven filtration media provides everything you need to elevate your liquid filtration product. Request a sample of this material and see for yourself, reach out to our nonwoven experts to discover how CFF™ can enhance your products.